| |

|

| In classical

open-column chromatography, the mobile phase flows

through the bed of column packing because of gravity.

This works (barely) with large-particle-size packings (particle

diameters larger than 50-100 microns or so), but

separation times can be extremely long. In order to

reduce separation time and allow the use of smaller

particle size packings (10 microns and below), we must

force the liquid mobile phase through the column under

pressure. This is the function of the pump (also called

the "solvent delivery system"): to maintain a

constant flow of mobile phase through the HPLC regardless

of the pressure (back pressure) caused by the flow

resistance of the packed column.

|

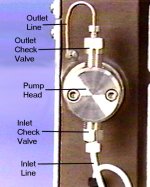

| Most

commercial HPLC pumps are based on a reciprocating piston

design, as shown here. A motor-driven cam pulls the

piston back and forth in the pump head. A flexible seal

around the periphery of the piston prevents leakage of

mobile phase out the back of the pump. Check valves

mounted in the head open and close in response to small

changes in pressure to maintain a one-way flow of solvent.

The pump cylinder

with its check valves is often accessible from the

outside to allow easier servicing of the check valves and

replacement of the pump seals. This part of the pump is

called the pump head.

|

Cross-sectional diagram

of a simple single-piston reciprocating pump

Typical pump head

assembly.

|

| |

|

| The

diagram below shows how pump flow varies with time:

During the

delivery stroke, flow increases from zero up to a maximum,

then decreases back to zero. During the intake stroke,

flow is zero. The pressure inside the pump changes in the

same way as flow -- going from zero to a maximum value,

then staying at zero during the intake stroke.

|

Single-piston

reciprocating pump operation.

|

| |

|

The kind of flow shown

above, where flow rate changes during the pumping cycle,

causes pressure pulses. Pulses are undesirable

for several reasons:

- they cause detection

problems

- they prevent good

quantitative analysis

- they lead to early

column failure.

Most of the differences in

pumps from different manufacturers are modifications to

give more uniform flow. One approach is to keep the

single-piston design, but to vary the shape of the cam

and /or the speed of the motor. This leads to a change in

the flow as shown at right. The shape of the cam leads to

a flatter flow curve at the middle of the delivery stroke.

In addition, the motor speeds up during the intake stroke

and slows down during the delivery stroke. Some pulsation

still remains, however, and these pumps often use some

form of "pulse dampening" to further reduce the

flow fluctuations.

|

|

Shaped (non-circular)

cam to minimize pressure pulses.

|

|

Output flow

from a shaped-cam pump.

|

|

| |

|

| Another common

approach combines the output flow from two heads

operating 180 degrees out of phase, such that the intake

stroke from one head coincides with the delivery stroke

from the second head. This means that while one cylinder

is filling the pump cylinder, the second cylinder is

delivering mobile phase. Then, when the second refilling,

the first cylinder delivers. We can combine these two

flows by feeding each pump output into a tee that

connects with the HPLC system. Now the combined flow of

both heads delivers a much smoother, less pulsing flow to

the LC system. The inlet line from the reservoir likewise

is fed to a tee that branches to feed both cylinders of

the pump. Pump pulsations can be reduced further by

special cam shapes, by varying the speed of the pump

motor, and by the use of pulse dampers.

|

|

| Another approach to

reducing pump pulsations while keeping the pump design

fairly simple is the Tandem Piston Pump. A large and a

small piston / cylinder unit are combined to provide

continuous flow of mobile phase from the pump. While the

large piston fills, the small piston delivers. When the

small piston fills, the large piston delivers enough

mobile phase to both fill the small piston and provide a

net flow of mobile phase to the LC system. Notice that

only three check valves are required for this pump versus

four check valves for a conventional two-piston pump.

|

A tandem-piston pump

provides a continous output flow.

|

| |

|

| Most LC pumps

(even those with multiple heads) have some pulsation in

the flow from the pump outlet. This is often smoothed out

by the use of a Pulse Damper. These devices typically

consist of a coil of flexible stainless-steel tubing.

When the pressure rises (as a result of flow pulsation),

the tubing stretches and its volume increases so that the

extra flow from the pump at this moment is accommodated

by the extra volume of the pulse damper. When the

pressure decreases, the tubing volume decreases, with the

extra solvent going to make up for the flow deficit. In

effect, the pulse damper acts as a hydraulic "shock

absorber" to smooth out pulsating flow.

|

|

| |

|