| |

|

| Degassing (How do

I degas thee? Let me count the ways). Four approaches are

commonly used to remove excess dissolved gas from mobile

phase solvents:

|

|

| 1.

Sonication. When pure solvents are mixed to make

up the mobile phase, excess dissolved gas escapes to form

bubbles (remember, air is less soluble in solvent

mixtures than in pure solvents). If the mobile phase

reservoir is placed in an ultrasonic bath, the sound

waves promote the coalescence of small bubbles which can

escape more easily. This type of degassing works for

premixed mobile phases by allowing the excess gas to

escape before it enters the pump. It is not recommended

for on-line mixing systems, in which bubbles form inside

the HPLC system, because it cannot reduce the

dissolved gas below the saturation level of the pure

solvent. Sonication is often used in conjunction with

vacuum degassing.

|

|

| 2. Vacuum.

This is very convenient because it can be combined with

vacuum filtration of the mobile phase to remove both

dissolved gas and particulate contamination. Like

sonication, with which it is often combined, this

technique works for premixed mobile phases, but is not

recommended for on-line mixing; it is a "one-shot"

technique, because the mobile phase immediately begins to

re-equilibrate with air.

|

Vacuum filtration is

often combined with sonication to remove excess dissolved

gas from premixed mobile phases.

|

| |

|

| 3. Helium sparge.

A stream of helium bubbles will sweep dissolved air out

of liquids (helium is virtually insoluble in most HPLC

solvents, so very little helium replaces the air). Helium

sparging is very effective; it can reduce the dissolved

air in common solvents to levels below the saturation

level of mixtures. This makes helium sparging especially

suitable for use with on-line mixing systems. While

helium sparging entails some risk of changing the mobile

phase composition by selectively evaporating the more

volatile components, this is usually not a problem if an

excessively vigorous flow of helium is avoided (in other

words, "don't overdo it!").

|

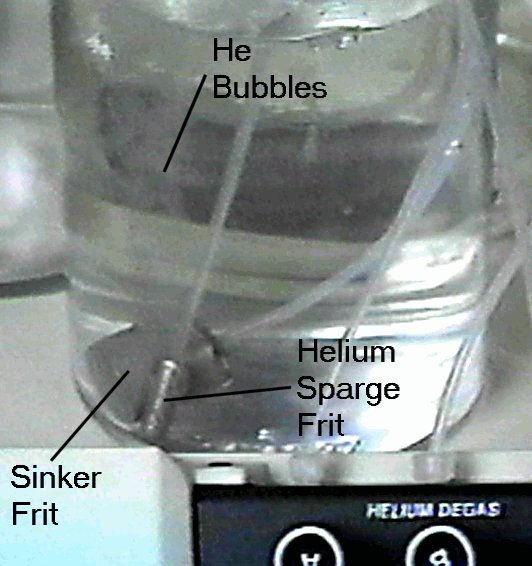

He sparge degassing

system. Note the large "sinker" frit on the

inlet line and the smaller helium sparging frit with the

plume of He bubbles rising through the mobile phase.

|

| |

|

| 4. On-line

membrane degassing. In many respects, this is

the most convenient approach to degassing. The mobile

phase or solvent flows through a hollow fiber made of a

semi-permeable membrane. A partial vacuum is maintained

on the outside of the membrane. Because air can diffuse

through the membrane while solvent vapor cannot,

dissolved air is removed from the solvent before it

reaches the pump. The membrane degassing module is

usually plumbed into the inlet line immediately upstream

of the pump, so that there is no opportunity for air to

redissolve.

|

A membrane degasser uses

a semi-permeable membrane passing through a vacuum

chamber. Gasses diffuse throught the membrane and are

removed. Solvents are retained.

|

| |

|