| |

|

| So far we have not talked

about the TUBING and FITTINGS that connect our various LC

modules together. For tubing connections between the

reservoir and the pump and the injector, the only

requirement is that the fittings not leak, and that the

tubing between the reservoir and the pump be large enough

in diameter so that flow of mobile phase to the pump is

not restricted. The tubing connections between the

injector and the column, and from the column to the

detector, however, require more attention.

|

Connections between the

reservoir and the pump are usually made with Teflon

tubing, often of fairly wide bore. Connections downstream

of the pump are usually made with stainless steel or PEEK

(poly ether ether ketone) tubing. Connections between

injector-column and column-detector should be made from

narrow-bore tubing (0.010" i.d. or less) in order to

minimize dead volume.

|

| |

|

| This part of

the LC system must be carefully designed and constructed

in order to minimize the volume of both the fittings and

tubing. We say that we have to eliminate dead volume

as much as possible. So we need to keep the tubing

length short, and we will usually use tubing of very

narrow diameter: 0.010 inch internal diameter (or "ten

thousandths") is the usual tubing size for this part

of the system (smaller tubing may be required for use

with "microbore" columns; larger tubing should

only be used with preparative columns). If for any reason

we have to replace the tubing or connections in this part

of the LC system (between the injector and detector), BE

VERY CAREFUL TO SELECT THE RIGHT TUBING SIZE AND THE

RIGHT FITTINGS.

|

|

| Let's

talk next about the fittings used in LC. These are called

compression fittings and their design is illustrated

below. A piece of

tubing is first equipped with a NUT and FERRULE as shown

at the right. To connect this end of the tubing with

another fitting (the column end, a tee, connector, etc.)

for the first time, just screw the nut into the fitting. Be

careful not to overtighten the fitting! Usually

the nut should be tightened finger-tight and then an

additional 3/4 of a turn (270 degrees clockwise) with a

wrench.

When reassembling an

existing fitting (when changing columns, for example),

the nut should be tightened finger-tight and then snugged

slightly with a wrench to prevent leaks.

|

Standard compression

fitting used in HPLC.

|

| |

|

| Unfortunately, not all

fittings are interchangeable. This is a major headache

for most LC workers, but we have to live with it for the

time being. Usually mismatched fittings appear to work,

and this makes the situation even worse. That is, the

fittings will appear to go together in the usual way.

However mismatched fittings will not work properly. The

reason is that the main difference in these fittings is

the distance between the tubing end and the ferrule, as

shown at the right.

|

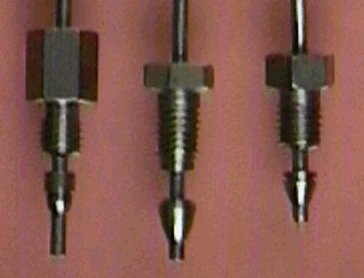

Note the difference in

the distance from the bottom of the ferrule to the end of

the tube in these three tube ends assembled with fittings

from different manufacturers.

|

| |

|

| If this

distance is too long for the body of the fitting, the

ferrule will not seat properly, and the fitting will leak.

If the distance is too short, the ferrule will seat, no

leak will occur, but a "dead volume" will be

created. This is most insidious, because then our

separation will not be as good as it should be, but

everything else will look OK. Dead volumes are like the

cancer of HPLC - hidden, but a real "killer".

Dead volume between the injector and the column permits

dilution of the initial sample with mobile phase, causing

band broadening. Dead volume between the column and the

detector cell undoes the separation already accomplished

on the column by allowing re-mixing of separated

components.

|

|

| The fittings for the ends

of the column are similar to tubing fittings. A ferrule

and nut on the column hold the column into the end

fitting - just like tubing is connected together. Because

the column is packed with small particles of column

packing, it is necessary to have a way to hold these

particles in the column. This is usually achieved with a

FRIT - a small, coin-shaped piece of sintered metal

having narrow pores. Most column frits are nominally 2-micron

porosity, although smaller frits (0.5 micron) are used

for columns of very small particles (3-micron diameter).

|

|

| |

|

| If we

disconnect the column end-fitting, we can see the frit on

the top of the column. This frit can be removed and

replaced with a new frit if the old frit becomes plugged.

However if we do this, WE HAVE TO BE VERY CAREFUL. If the

column packing at the inlet is disturbed, it could ruin

the column permanently.

|

|

| |

|